How to Make Feed Pellets?

The demand for animal feed pellets is growing worldwide. After all, feed pellets are nutritious yet affordable food for animals.

Let us learn how to make feed pellets for animals.

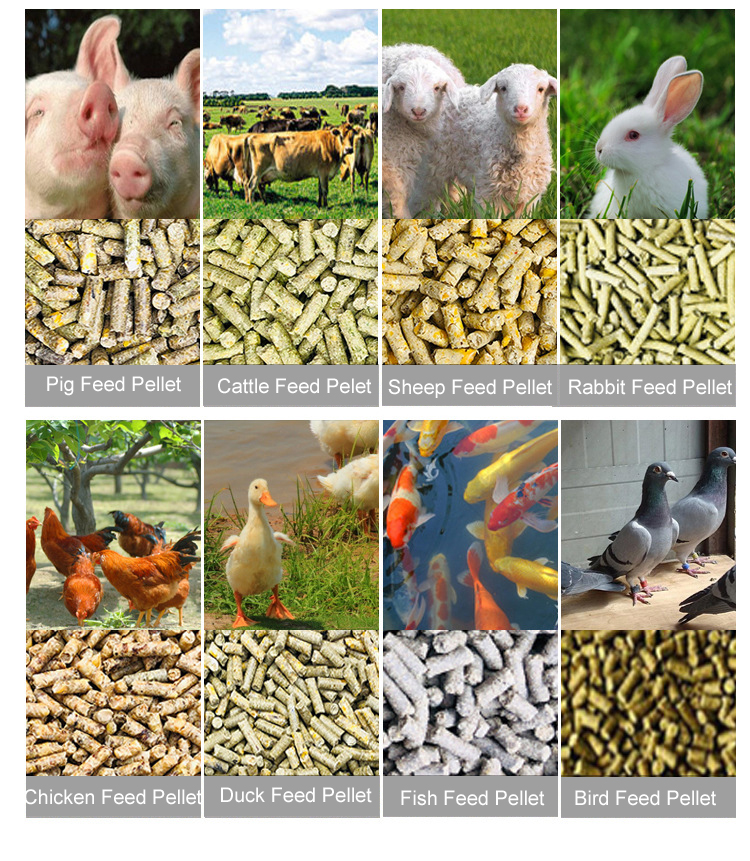

Depending on the animals you have, you can make cattle feed pellets, chicken feed pellets, and more.

You can also start an animal feed pellet business.

However, for that, you need a high-quality animal feed pellet-making machine.

The feed pelleting process involves the following steps:

Choose Ingredients for Feed Pellets

Since animals do not get all the nutrients from one plant or grass type, their pellets are a mixture of different ingredients.

Ingredients for animal feed pellets can vary based on the dietary requirements of your animals.

For example, if you are making feed pellets for cows, follow the cattle feed pellets formula. It is a mixture of bran, rapeseed cake, corn, minerals, and more.

Similarly, if you are making chicken feed pellets, choose ingredients accordingly. They must have a perfect balance of protein, vitamins, and minerals.

It is advisable to seek the advice of an expert.

Mixing and Grinding

Once you have accumulated all the required ingredients, it is time to mix and grind them. Use feed mixtures and grinders for this process.

Since ingredients have a consistent ratio of different nutrients, mix them properly. Otherwise, feed pellets won’t be uniform in texture.

Pelletizing

This process involves putting mixed ingredients into the animal feed pellet-making machine. The pellet mill processes the raw material and makes pellets out of it.

The cattle feed pellet machine consists of a die and rollers. When you put ingredients into the machine, rollers push them toward the die so that they can pass through its holes.

Pressure and friction created during this process turn raw material into the shape of pellets as they pass die holes.

Cooling

Once feed pellets are out of the machine, they undergo a cooling process.

When feed pellets come out of their maker, they are extremely hot. Cooling machines reduce their temperature.

It helps in maintaining the shape of pellets and moisture level. If you do not have this equipment, you can opt for open-air drying.

Packaging and Storage

Proper packaging and storage have a significant role in maintaining the quality of animal feed pellets.

Store your pellets in a dry place. Also, choose high-quality packaging material to pack them. It will also help in their transportation and distribution.

So this is a quick feed pelleting process. To make the most out of your animal feed pellet business, keep the following things in mind.

Use nutrient-rich ingredients for making animal feed pellets.

Don’t neglect the maintenance of your animal feed pellet-making machine.

Store your pellets in a cool and dry place to maintain their quality for a long time.